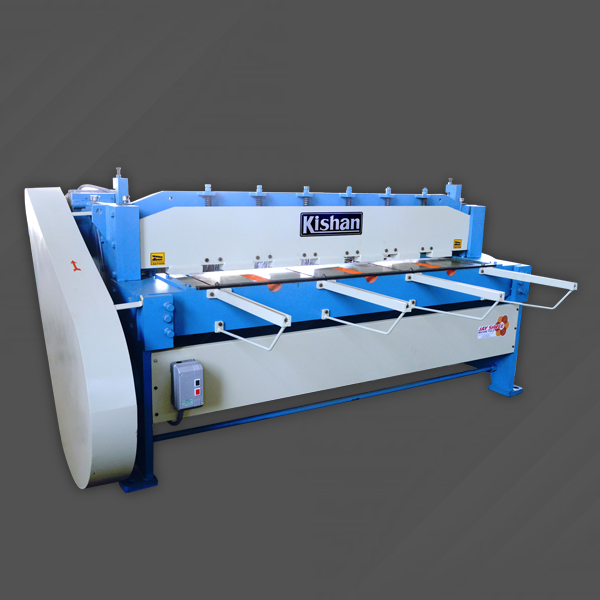

Mechanical Under Crank Shearing Machine

KISHAN brand steel body geared operated shearing machine are designed and parallel sheet cutting. The machine is applicable to M.S., S.S., COPPER, BRASS, ALUMINIUM, CRC, P.S.B., etc. cutting industries. it is also applicable to manufacturers of electric stamping, automobiles, tin drum barrel, control panels, and board, steel furniture, tube light patties, fabricators & kitchenware items, etc.

SIDE FRAMES are steel plates designed for maximum rigidity to eliminate deflection and to withstand continuous high-speed performance at full capacity.

RAM (UPPER BEAM): is of the solid steel plate and additional ribs on the backside the ram adds to its strength, carrying the upper knife. Its maximum weight ensures a lesser load on the bearing. the ram moves inaccurate machine guide-ways to avoid deflection. for smooth running and maintains the proper strength of the upper knife.

TABLE is of closed box type steel fabricated, which forms a rigid backbone for the share and a solid backing for the lower knife. Additional ribs, under the table, adds to its strength.

CRANKSHAFT & FLYWHEEL SHAFT: is of the best steel, accurately machined, and runs in gunmetal bearing and all other installed in gunmetal bearings.

BLADE: is four edged HcHcR provided for longer tool life.

HOLD DOWN: is of steel fabricated spring-loaded ensures uniform pressure throughout the cutting length without any slipping irrespective to the sheet.

ROLLING KEY CLUTCH: made of EN-24 steel for positive engagements and continuous operation having three key ways. The single revolving key system is incorporated in the machine ensuring easy and efficient working of the machine.

DRVIE: is through “B” belts on the flywheel and other chains of job cut gears for smooth running and longer life.

BRAKE: the constant spring-loaded adjustable brake is provided.

LUBRICATION: for sufficient lubrication oil cups and oil points are provided.

STANDARD ACCESSORIES: gear & wheel guard, hand-operated back gauge, manual lubrication system, t-slot front supporters, front scale gauge, instruction manual book

OPTIONAL ACCESSORIES: automatic lubrication system, electrical consists of an electric motor, control panel, v-belts, stroke counter, ball roller or ball transfer, squaring arm, foundation bolts, motorized back gauge with D.R.O.

Specifications for Mechanical Under Crank Shearing Machine

| Model | Cutting Cap. In MS Length X Thickness | Stroke per minute | Table Height | Table Width | Front Guage | Rear Guage | Motor HP/KW | Blade Length X Width X Thick | Overall Dimension in MM (APP) | ||

| Length A | Breadth B | Height C | |||||||||

| KSUG-1 | 610 X 1 | 120 | 700 | 250 | 600 | 450 | 1/.75 | 610X50X12 | 1200 | 900 | 1100 |

| KSUG-2 | 1000 X 1 | 120 | 700 | 250 | 600 | 450 | 1/.75 | 1000X50X12 | 1600 | 900 | 1100 |

| KSUG-3 | 1270 X 1 | 120 | 750 | 300 | 600 | 600 | 1/.75 | 1270X50X12 | 1900 | 900 | 1200 |

| KSUG-4 | 1525 X 1 | 120 | 750 | 300 | 600 | 600 | 1/.75 | 1525X50X12 | 2150 | 900 | 1200 |

| KSUG-5 | 2030 X 1 | 120 | 750 | 300 | 600 | 600 | 2/1.5 | 2030X50X12 | 2550 | 1100 | 1200 |

| KSUG-6 | 2540 X 1 | 120 | 800 | 350 | 600 | 600 | 3/2.2 | 2540X50X12 | 3100 | 1400 | 1200 |

| KSUG-7 | 3125 X 1 | 120 | 800 | 350 | 600 | 600 | 5/3.7 | 3125X63X14 | 3500 | 1400 | 1200 |

| KSML-1 | 610 X 2 | 55 | 700 | 300 | 600 | 600 | 2/1.5 | 610X63X12 | 1250 | 1000 | 1100 |

| KSML-2 | 1000 X 2 | 55 | 700 | 300 | 600 | 600 | 2/1.5 | 1000X63X12 | 1700 | 1000 | 1100 |

| KSML-3 | 1270 X 2 | 55 | 750 | 350 | 600 | 600 | 2/1.5 | 1270X63X12 | 2000 | 1500 | 1200 |

| KSML-4 | 1525 X 2 | 55 | 750 | 350 | 600 | 600 | 2/1.5 | 1525X63X12 | 2300 | 1500 | 1200 |

| KSML-5 | 2030 X 2 | 55 | 750 | 400 | 600 | 600 | 3/2.2 | 2030X63X14 | 2700 | 1600 | 1200 |

| KSML-6 | 2540 X 2 | 55 | 800 | 400 | 600 | 600 | 5/3.7 | 2540X63X14 | 3200 | 1600 | 1200 |

| KSML-7 | 3125 X 2 | 55 | 800 | 400 | 600 | 600 | 5/3.7 | 3125X63X14 | 3800 | 1600 | 1200 |

| KSMH-1 | 610 X 4 | 50 | 750 | 350 | 600 | 600 | 3/2.2 | 610X63X14 | 1300 | 1400 | 1200 |

| KSMH-2 | 1000 X 4 | 50 | 800 | 350 | 600 | 600 | 5/3.2 | 1000X63X14 | 1750 | 1400 | 1200 |

| KSMH-3 | 1270 X 4 | 50 | 800 | 400 | 600 | 600 | 5/3.7 | 127X63X14 | 2050 | 1500 | 1200 |

| KSMH-4 | 1525 X 4 | 50 | 900 | 450 | 600 | 600 | 5/3.7 | 1525X75X18 | 2350 | 1700 | 1300 |

| KSMH-5 | 2030 X 4 | 50 | 900 | 450 | 600 | 600 | 7.5/5.6 | 2030X75X18 | 2750 | 1700 | 1300 |

| KSMH-6 | 2540 X 4 | 50 | 900 | 450 | 600 | 600 | 10/7.7 | 2540X75X18 | 3300 | 1800 | 1350 |

| KSMH-7 | 3125 X 4 | 40 | 900 | 450 | 600 | 600 | 15/11.2 | 3125X75X18 | 3900 | 1800 | 1350 |